The Properties of Compression Springs

Contents |

[edit] Introduction

Compression springs are the most commonly-used type of spring as well as the most economical, making it an important spring within the manufacturing industry. Aside from manufacturing, they are also used in a range of other industries including:

- Transportation.

- Construction.

- Materials handling.

- Agricultural.

- Aeronautical.

Compression springs can sometimes be confused with torsion springs due to their similarities in appearance; however, they are designed to do very different things.

[edit] What Is a compression spring?

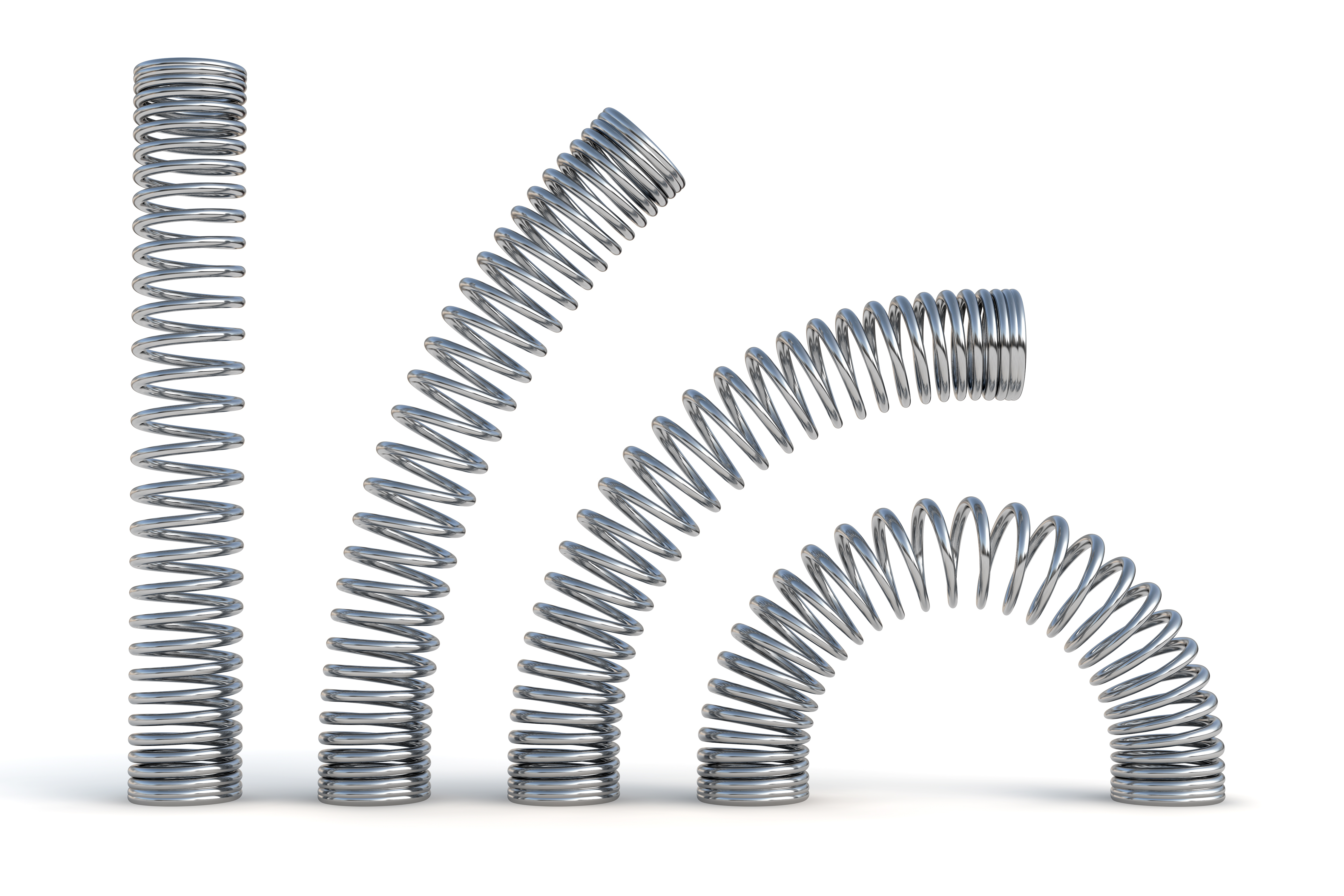

Compression springs are open-coiled springs wound into a helical shape. They are designed to offer resistance to a compressive force applied axially, meaning that they push back when force is applied to them. Helically-wound compression springs are the most common configuration and have an extensive range of uses.

Compression springs can be formed in many different types such as:

- Conical.

- Hourglass.

- Barrel-shaped.

- Torsional.

- Magazine.

They are typically positioned over a rod or fitted into a hole. When subject to pressure by weight on their axis, the spring compresses. As it does this, it gains the potential to push back to its original position.

[edit] History of use

Some form of spring technology has existed for thousands of years. The earliest known application of spring technology is the bow and arrow. Coiled springs, however, did not appear until early in the 15th century.

These first compression springs were used in door locks in the 18th century to ensure that only one specific type of key could be used to unlock a door. They were later used in the first spring-powered clock that evolved into the first watches of the 16th century.

In 1676, British physicist Robert Hooke postulated Hooke’s law, which states that the exertion of a spring is proportional to the load applied to it, so long as this load does not exceed the material’s elastic limit.

[edit] Properties of compression springs

A feature that can set compression springs apart from other types of spring is the tightness of their coils. Compression springs are less tightly coiled than torsion springs and work in the opposite way to other springs – whereas some springs hold things together, compression springs keep things apart.

Compression springs are typically made from metal due to the stiffness of the material, particularly high strength alloys. A compression spring is fully extended when at rest. However, upon compression, the spring will express stored torsional energy in a pushing force. The shape-restoring force is proportional to the deflected distance of the spring.

[edit] Common uses of compression springs

Compression springs have many different purposes and functions. Probably the most famous use of a compression spring is the pogo stick. Thought to be originally patented in 1891, it rose to popularity in the 1970s, loved by children around the world.

Some more common uses of compression springs that we come across every day include:

- Valves.

- Locking doors.

- Railways.

- Electrical switches.

- Large stamping presses.

- Ballpoint pens.

Being the most common type of spring, the bulk of those manufactured are used in engineering, the defence industry and in vehicles.

[edit] Related articles on Designing Buildings Wiki

- Compression springs.

- Die springs.

- E-spring.

- Flat springs.

- Key qualities of springs.

- Large and Hot Coiled Compression Springs.

- Spring materials.

- Tension springs v torsion springs.

- The Difference Between Tension and Torsion Springs.

- The importance of gas springs.

- The Multiple Uses of Compression Springs.

- The Uses of Wire Forms Within the Construction Industry.

- Using springs in construction to prevent disaster.

- Wave springs.

Featured articles and news

ECA progress on Welsh Recharging Electrical Skills Charter

Working hard to make progress on the ‘asks’ of the Recharging Electrical Skills Charter at the Senedd in Wales.

A brief history from 1890s to 2020s.

CIOB and CORBON combine forces

To elevate professional standards in Nigeria’s construction industry.

Amendment to the GB Energy Bill welcomed by ECA

Move prevents nationally-owned energy company from investing in solar panels produced by modern slavery.

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Heat pumps, vehicle chargers and heating appliances must be sold with smart functionality.

Experimental AI housing target help for councils

Experimental AI could help councils meet housing targets by digitising records.

New-style degrees set for reformed ARB accreditation

Following the ARB Tomorrow's Architects competency outcomes for Architects.

BSRIA Occupant Wellbeing survey BOW

Occupant satisfaction and wellbeing tool inc. physical environment, indoor facilities, functionality and accessibility.

Preserving, waterproofing and decorating buildings.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.